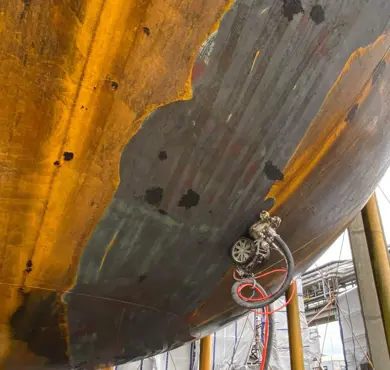

One of our services within robotic services is robotic surface treatment.

Our innovative approach to surface maintenance revolutionizes traditional methods. This work requires a set-up of scaffolding, sandblasting and painting, as well as strict attention to health, environment and safety (HSE) for the workers. Now, with our advanced technological solutions, we have implemented robotic technology for pretreatment and surface preparation.

Using robotic solutions for surface treatment offers several advantages:

- Great health benefits through less strain on the operator's body

- Great environmental benefit when collecting paint waste

- Reduced CO2 emissions

- Very good quality of pre-treated surface

- Far more efficient implementation than traditional methods both in the pre-treatment and application phase

- Reduced need for scaffolding on large surfaces

In collaboration with our subsidiary, Remotion, we offer comprehensive solutions that are specially adapted to your unique needs in robotic surface treatment.

The use of robots not only ensures more sustainable maintenance, but also reduces physically taxing tasks for our professionals. The solutions are:

- Effective

- Environmentally friendly

- Protective of our employees against noise and vibrations

The use of pre-treatment robots in paint maintenance provides significant health benefits. Our personnel avoid the physically demanding work and exposure to vibrations that often accompany traditional ultra-high pressure (UHT) and blowing methods. In addition, we use Electric High-Pressure Pumps, which not only make the pre-treatment process more efficient, but also help to reduce CO2 emissions significantly. These electric pumps also offer greater flexibility in setting up equipment offshore, thanks to lower noise levels and no hot exhaust.

Our expertise in robotics has grown significantly, particularly with the development of remote-controlled robots that clean surfaces using high-pressure water. In this process, paint waste is effectively sucked up using vacuum technology and collected in containers, which significantly reduces the risk of microplastic discharge, particularly in areas with a high risk of discharge into the sea.