Maintenance of large industrial tanks is a comprehensive process with setting up scaffolding, sandblasting and painting each individual tank, in addition to ensuring good HSE for those who will carry out the work. With our new technological solutions, robotic solutions are used for pre-treatment and preparation of surfaces. By adopting robots, we ensure sustainable maintenance and reduce challenging and burdensome tasks for professionals. The solutions of the future are both efficient and environmentally friendly, in addition to saving employees from noise and vibrations.

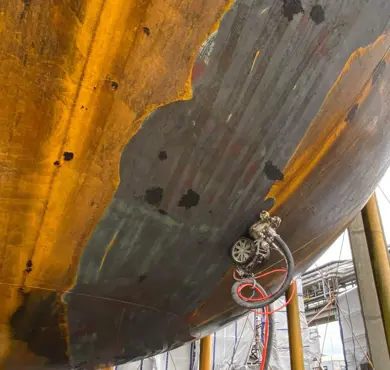

In line with our development in robotics, we have gained extensive experience with the use of remote-controlled robots that blow the surface using water under pressure (2500 bar). In the same operation, all paint waste is sucked up using a vacuum and collected in containers. This contributes to reduced discharge of microplastics in areas where the risk of discharge to the sea is high.

There are good health benefits from using pre-treatment robots for paint maintenance. Personnel are saved from physically demanding work, as well as exposure to vibrations which are normally a consequence of traditional UHT and blowing methods. Electric High-Pressure Pumps can be used together with the robots, the use of electric UHT has given us the opportunity to make pre-treatment more efficient while preventing significant CO2 emissions, electric pumps also provide greater opportunity for equipment placement offshore due to reduced noise levels and no hot exhaust.