The development of corrosion is quite unpredictable and depends on several well-known factors. Two of the key factors are damage/defect in the paint film and the presence of water, therefore the first line of defense against CUI is to avoid damage to the paint film during insulation and to keep the water out (waterproofing) of the insulation system.

Different insulation systems use different methods to protect the insulation system from water. The insulation system often has a stainless steel casing, a non-metallic casing or an integrated weather-resistant surface. The common problem with all of these is that the waterproofing barrier can be compromised due to aging/failing sealant or mechanical damage.

When water or water vapor enters the insulation system, it can become trapped and have great difficulty drying out. It is a common expression that it is waterproof if the water cannot get out, because it will always get in. Therefore, drainage and/or detection of water beneath the insulation is essential to reduce the potential for corrosion and focus physical inspection on areas where water is detected.

WUI drain plug Detecting Plug

Corrosion under insulation (CUI) causes billions of dollars in maintenance costs for oil and gas facility owners each year. This is due to the high costs associated with carrying out periodic and site-specific inspections and maintenance to deal with CUI. Significant amounts of uncorroded pipes and process equipment are stripped for inspection despite being in perfect condition. Inspection for water and corrosion under insulation is expensive and often carried out with low accuracy.

The Benarx WUI Drain Detection Plug is a drain plug designed to indicate the presence of water inside the insulation, to help facility owners and maintenance planners perform more precise inspection work against areas with wet insulation and higher probability of CUI. The WUI Drain Detection plug is equipped with a bright yellow indicator part that pops out if liquid water flows through the plug over a period of a few days.

The plug-in is a tool that helps identify areas for inspection and thus enables more precise risk-based CUI inspection that saves costs and time.

Read more about the product here

End Cap

The end of the pipe insulation is a critical point where moisture can penetrate and cause corrosion. It is crucial to prevent water ingress into the insulation system. Water in and under insulation is one of the main causes of corrosion under insulation, so-called CUI.

Using traditional end caps in steel has countless challenges during and after the installation phase:

- Cut injuries

- Damage to heating cable and paint film

- Insulators who drill holes in pipeline during installation in an attempt to drill holes for pop rivets

- Major challenges with the production and quality of end terminations are suitable for thin pipe systems

- Poor waterproofing

- Slow installation

By using silicone end caps which are enchantingly easy to install, the saving in installation time is huge in the installation phase, while avoiding all the problems associated with traditional steel end caps:

- No cuts = better HSE

- No scratches/damage to paint film or pipes during insulation = less CUI

- No cut damage to heating cable during insulation

- No need for cable "bananas" in stainless steel to protect heating cable through end base.

- No requirement for enclosure expertise for correct installation

- Can be mounted in advance to mark the start-end of insulation on the pipe, to facilitate measuring and mounting of insulation and boxes on pipes.

Read more about the product here

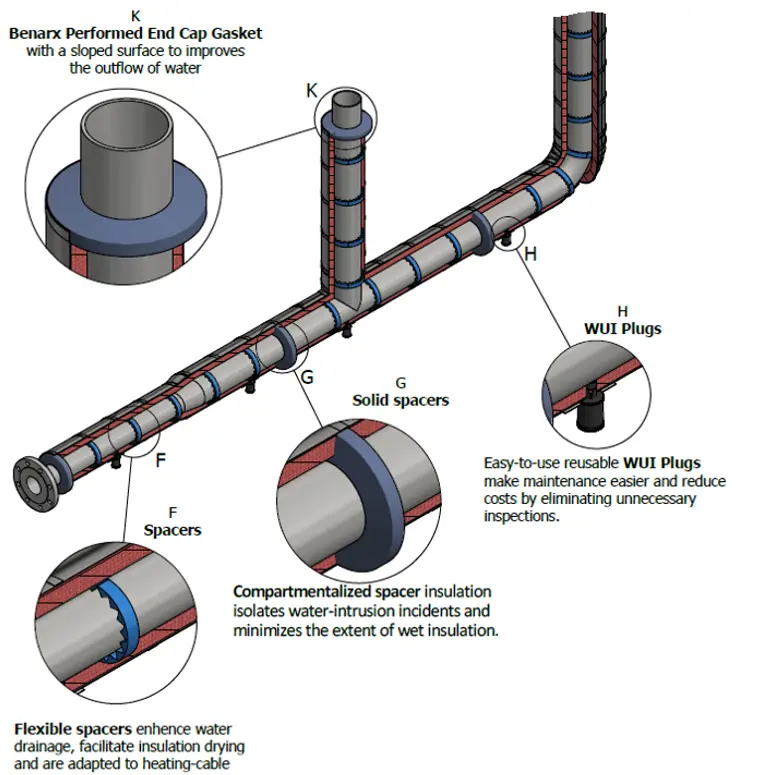

Benarx CUI Reducing Insulation Concept

Beerenberg has carried out a series of CUI tests to find out what characterizes an insulation system that reduces the amount of CUI that occurs and minimizes maintenance costs. We have summarized this in what we call the Benarx CUI Reducing Insulation Concept, which can be summarized in a few simple points that describe "best practice" in the design of an insulation system for reduced CUI.

- Use of air-gaps / spacers to break direct contact between insulation and pipes. This prevents wet insulation from being in direct contact with the pipe and improves the drainage and drying properties of the insulation system

- Benarx Preformed End Cap Gasket for better integrity against water ingress at terminations

- Segmentation at regular intervals, so that a point of water penetration does not have consequences for larger stretches of pipe. This also prevents ventilation effects and chimney effects (drafts through the insulation) which can be an unintended consequence of distance insulation.

- Use of WUI detection plugs for more precise mounting and maintenance of water under insulation.

- Use water-repellent / hydrophobic insulation materials as these improve drainage and prevent the absorption of water in the insulation.

- Use of non-metallic enclosure (GRP). This enables inspection with an infrared camera which can effectively reveal damp insulation through the bridges it causes. GRP casing is also transparent to other types of inspection devices used for the detection of corrosion on the pipe directly.

Benarx CUI Reducing Insulation Concept