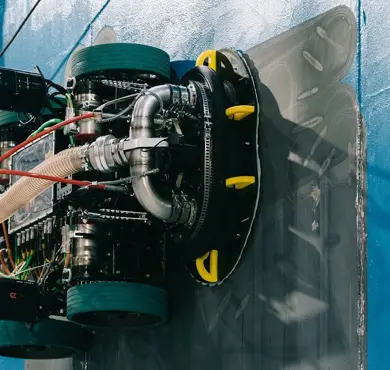

Beerenberg uses robots to ensure safe, sustainable, and efficient maintenance services on the FPSO ship hull at an oilfield east of Rio de Janeiro. Here, 3,800 square meters are to be painted by mid-May, making this project the world’s largest robotic operation of its kind.

The robots provide much needed quality maintenance in a climate that accelerates corrosion – and they do so with improved safety, reduced risk, and reduced emissions. This is good news for oil and gas companies in a region where the need for maintenance is increasing along with the activities – and they are investing in new technology, equipment, and maintenance services to resume production.

With an increasing demand for efficiency, accuracy, and cost reduction, robotics becomes a key component to meet the requirements. Robots enhance productivity and improve safety standards and precision in complex maintenance operations.

High quality, safer, and more sustainable

For Berenberg’s personnel, the robotic services provide reduced risk in the execution phase and burden on the executing personnel. Use of robotics to also contributes to less exposure to noise, vibration, dust, and chemicals. For the environment, using robots reduce CO2 emissions, and emissions of microplastic and sand to almost zero, compared to sandblasting, water-jetting and mechanical surface preparation. At the FPSO ship hull, the reduction is 99 percent, and all waste collected and handled appropriately. The quality and efficiency of ship hull maintenance is also better with robotic services, thus contributing to the environment and lifespan of the facilities.

Robotics can also play a significant role in enhancing the economic sustainability of the industry. By reducing waste, increasing efficiency, and minimizing the risk of human errors, robots can contribute to more sustainable operations and reduced costs in the long run.

Growing interest and development

Due to these advantages, there is a growing integration of robotics in the industry. Alongside advanced robotic systems for inspection, maintenance, and repair of equipment, robotic solutions ensure automation of repetitive tasks. Beerenberg is at the forefront of using these technological advancements in the industry. – In the grand scheme of things, robotics will not only transform work processes but also contribute to shaping the future landscape of the industry. It is crucial to proactively embrace these changes to ensure a sustainable future for ISS-related operations, says Toni Suomäki, EVP.

Advanced Solutions

Beerenbergs subsidiary, Remotion, says robotics provide the opportunity to deliver services more swiftly and accurately while minimizing margins of error. – Our customers are increasingly seeking solutions that are not only cost-effective but also precise and reliable. Their expectations also include a heightened degree of data driven insights, which robots can contribute to through continuous monitoring and analysis, says Erik Svenheim in Remotion.