Beerenberg has 47 years of experience in maintenance and modification services.

We handle the entire spectrum from field studies and new construction to maintenance and modifications, with a constant focus on strengthening HSEQ with energy- and cost-effective and sustainable solutions.

We deliver expertise and comprehensive services within:

- Architect and decorator

- Electricity and habitat

- Engineering and technical services

- Insulation

- Mechanical services

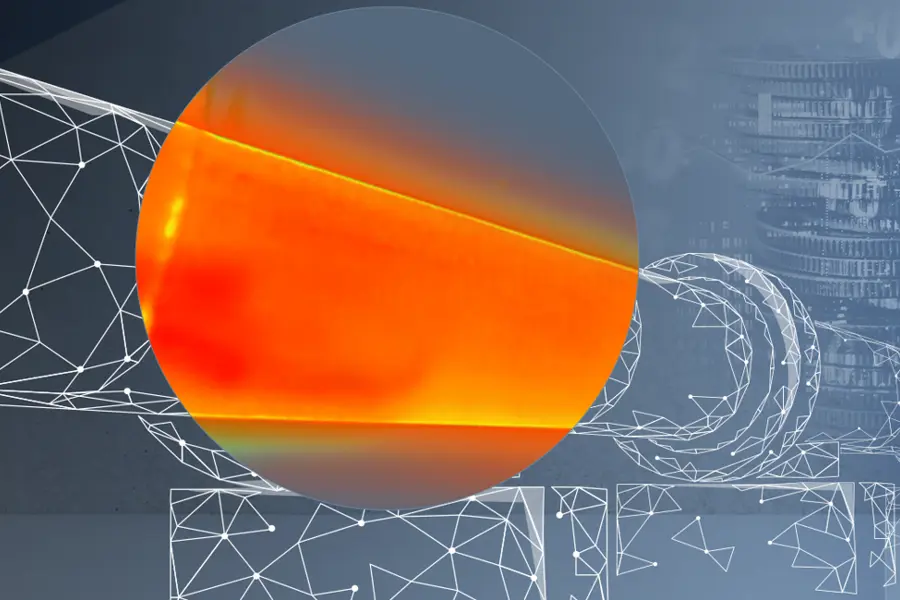

- Surface treatment

- Robotic services

- Scaffolding and access

- Subsea